When it comes to pharmaceutical packaging, child-resistance is non-negotiable—but how you achieve it can vary.

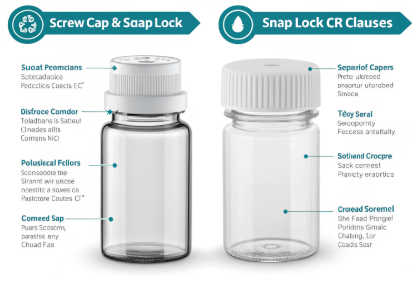

Screw cap and snap lock closures are two common child-resistant (CR) options, each with unique mechanisms, safety profiles, and regulatory implications. Choosing the right one depends on product type, market, and user demographics.

Here’s how these two CR systems compare and how to make the best decision for your brand.

What Defines a Child-Resistant Closure in Pharmaceutical Packaging?

It’s not just about making it harder to open—it’s about passing strict safety protocols.

A child-resistant closure (CRC) must prevent access by most children under five while remaining accessible to most adults, according to standards like ISO 8317 and 16 CFR 1700.20.

Key Requirements for CR Closures

| Standard | Requirement |

|---|---|

| ISO 8317 | Tested with 200 children (age 42–51 months) and 100+ adults |

| ASTM D3475 / 16 CFR 1700.20 | Must resist access by ≥85% of children, be usable by ≥90% of adults |

| Health Canada CCCR-2001 | Visual + tactile compliance, bilingual labeling, adult re-sealability |

At PauPack, all CR closures undergo certified third-party testing and come with panel pass rates, torque specs, and adult usability data.

How Do Screw Caps and Snap Lock Systems Differ in Mechanism and Safety?

Both aim to protect—but their engineering is fundamentally different.

Screw caps use a push-down-and-turn method, while snap lock systems require a simultaneous squeeze, press, or lift motion to disengage. Each design targets a child’s cognitive and physical limitations.

Mechanism Comparison

| Closure Type | How It Works | Safety Focus |

|---|---|---|

| Screw Cap | Push down while turning | Requires hand coordination, strength |

| Snap Lock | Press side tabs, squeeze to unlock | Challenges dexterity and logic |

| Hybrid CR Cap | Twist with button press or lock tab | Maximum protection, slower access |

Screw caps are common for liquids, capsules, and OTC drugs, while snap locks are often used for dry items, topical creams, or single-dose packaging.

Which Closure Type Offers Better Compliance with Global CR Standards?

Different regions may favor one type over the other—but both can pass testing if engineered properly.

Both screw caps and snap locks can meet global CR standards. However, screw caps have broader acceptance in pharmaceutical applications due to longer use history and better adult compliance metrics.

Global Acceptance Snapshot

| Region | Preferred Closure Type | Note |

|---|---|---|

| US (FDA/CPSC) | Screw cap | Most common for Rx and OTC meds |

| EU (EMA) | Either, if ISO 8317 passed | Snap locks gaining ground |

| Canada | Snap locks for household chemicals | Screw caps for pharma and supplements |

| Australia | Screw caps for oral solids/liquids | Snap locks for creams, balms |

At PauPack, we offer closures certified under both ISO and ASTM, helping brands navigate compliance for North America, Europe, and APAC markets.

What’s the Impact of Each Closure Type on End-User Usability and Risk?

Child-resistant shouldn’t mean user-resistant.

Screw caps are generally easier for older adults to operate, while snap locks can be harder to grip or understand—especially in low-light or emergency use. However, both need adult testing to confirm real-world performance.

Usability Impact Breakdown

| Factor | Screw Cap | Snap Lock |

|---|---|---|

| Opening Time | Faster | Slower |

| One-Hand Operation | Difficult | Very difficult |

| Elderly Accessibility | Higher | Moderate to low |

| Instruction Clarity | High (text/arrow) | Medium (symbol-based) |

| Tamper Evidence | Available with band | Integrated with lock design |

PauPack supports packaging teams with CR cap mockups and user trials, especially for senior-targeted meds or fast-response supplements.

How PauPack Helps Pharma Brands Choose the Right CR Solution for Each Product?

One closure doesn’t fit all—especially in pharma.

PauPack provides pharma clients with tailored CR closure recommendations based on formulation (liquid, powder, cream), dose format, and target region—with full OEM support and compliance documentation.

What We Offer

-

ISO 8317 / ASTM D3475-certified screw and snap lock caps

-

CR-compatible bottles from 10ml to 250ml

-

Panel test data, torque specs, and certification bundles

-

Custom CR mold development for unique products

-

DDP shipping and regulatory consulting for US, EU, CA, AU

Whether you're launching a vitamin line or expanding a dermatology formula, PauPack ensures your CR closure protects your product—and your brand.

Which Pharmaceutical Products Pair Best with Screw Cap or Snap Lock Closures?

It all starts with the formula. The product inside determines which closure type will serve best.

Screw caps are ideal for oral liquids, capsules, and tablets, while snap locks work better for semi-solid products, single-use units, or topical applications.

Closure Pairing by Product Type

| Product | Recommended Closure | Why |

|---|---|---|

| Liquid medication (syrups, drops) | Screw Cap | Seals tightly, supports droppers/measuring cups |

| Capsules/tablets | Screw Cap | Familiar, resealable, dosage-friendly |

| Creams and balms | Snap Lock | Wider opening, easier access |

| Single-dose topical vials | Snap Lock | Quick-release, low-volume format |

| Child vitamin gummies | Screw Cap | High tamper-resistance + reclosure |

At PauPack, we help pharma brands assess viscosity, delivery method, and shelf life to align closures with product performance and dosage needs.

How Do Production and Material Costs Compare Between the Two Closure Types?

Efficiency is everything—especially in high-volume pharma lines.

Screw caps tend to have lower mold and material costs due to simpler geometry, while snap locks may require higher tooling investment and slower cycle times.

Cost Structure Comparison

| Cost Factor | Screw Cap | Snap Lock |

|---|---|---|

| Mold Development | Lower | Higher due to moving parts |

| Unit Cost (bulk) | $0.04–$0.09 | $0.06–$0.12 |

| Cycle Time | Faster | Slower due to multi-step molding |

| Decor Options | Easier (flat lid, top logo) | Limited space for branding |

| MOQ Flexibility | Higher | May require higher base run |

At PauPack, we support short-run clients with stock CR options, and offer sliding-scale pricing for screw and snap systems based on order volume and assembly method.

What Are the Automation Implications for Each Closure in High-Speed Packaging?

Choosing the wrong cap type can bottleneck your entire production line.

Screw caps integrate easily into most automated filling lines, while snap locks may need custom pick-and-place or press-fit modules—adding complexity and cost.

Automation Readiness

| Metric | Screw Cap | Snap Lock |

|---|---|---|

| Inline Capper Compatibility | Yes | Sometimes |

| Torque Control | Straightforward | Not applicable (uses snap fit) |

| Assembly Speed | High | Medium |

| Inspection Integration | Easier (torque/height sensors) | Harder to detect full engagement |

| Changeover Time | Minimal | Higher for shape-specific feed rails |

Our engineering team at PauPack reviews filling line specs and packaging automation workflows with clients during the prototyping phase—ensuring closure choice won’t slow production.

How Do Patients Perceive Convenience and Safety Across Closure Styles?

Packaging isn’t just regulatory—it’s emotional. Your closure must balance trust and ease.

Screw caps are more familiar and easier to open for seniors and caregivers, while snap locks are often perceived as more secure—but sometimes confusing or difficult to operate.

Patient Feedback Trends

| Factor | Screw Cap | Snap Lock |

|---|---|---|

| Perceived Safety | High (common in Rx) | Very high (less tampering) |

| Ease of Use for Seniors | Higher | Lower (grip/logic issues) |

| Child Deterrence | Effective | Very effective |

| User Confidence | Consistent | Depends on label clarity |

| Instruction Need | Low | High (icons or on-pack directions) |

PauPack offers on-pack guidance design services (QR codes, usage icons) to help brands explain snap lock use in DTC or retail environments, improving patient trust and adoption.

How PauPack Streamlines CR Cap Integration from Prototyping to Global Launch?

You shouldn’t have to choose between safety and scalability.

PauPack helps pharmaceutical and wellness brands test, certify, and mass-produce CR closures—offering screw and snap lock options that meet ISO 8317 and ASTM D3475 standards.

Our CR Cap Support Includes:

-

🧪 Certified ISO 8317/ASTM D3475 closures in screw or snap format

-

📦 Stock mold options for fast launch, or custom CR molds

-

🧴 Dropper/pump/liner integration for hybrid packaging

-

🧾 Documentation packs for FDA/EU/Health Canada

-

🧠 Production compatibility consulting for automation lines

-

🌍 Global shipping + DDP fulfillment for regulated markets

Whether you’re preparing for OTC distribution, clinical trials, or direct-to-patient packaging, PauPack delivers CR closure solutions that meet global standards and scale with your growth.

Conclusion

Both screw caps and snap locks meet child-resistance standards—but the right choice depends on your product, patients, and production line. PauPack helps you make that decision with clarity, speed, and full compliance from start to shelf.